Since Rhino is a mathematically accurate NURBS modeler, tools that provide accurate information about the objects are provided.

Some analysis commands provide information about location, distance, angle between lines, and radius of a curve. For example:

| ● | Distance displays the distance between two points. |

| ● | Angle displays the angle between two lines. |

| ● | Radius displays the radius of a curve at any point along it. |

| ● | Length displays the length of a curve. |

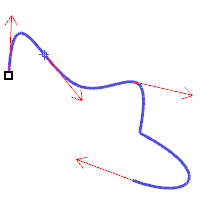

Curves and surfaces have a direction. Many commands that use direction information display direction arrows and give you the opportunity to change (flip) the direction.

The Dir command displays the direction of a curve or surface and lets you change the direction.

The illustration shows the curve direction arrows. If the direction has not been changed, it reflects the direction the curve was originally drawn. The arrows point from the start of the curve toward the end of the curve.

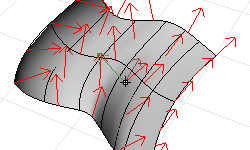

The Dir command also displays surface u-, v-, and normal direction. Surface normals are represented by arrows perpendicular to the surface, and the u- and v-directions are indicated by arrows pointing along the surface. Closed surfaces always have the surface normals pointing to the exterior.

The Dir command can change the u-, v-, and normal-directions of a surface. This direction can be important if you are applying textures to the surface.

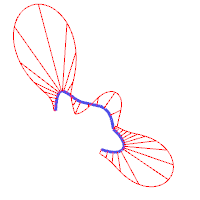

Curve analysis tools let you turn on a graph showing the direction perpendicular to the curve at a point and the amount of curvature, display a curvature circle, test the continuity between two curves and the intervals of overlap between the two curves.

The CurvatureGraph command displays a curvature graph on curves and surfaces. The lines on the graph represent a direction perpendicular to the curve at that point. The length of the line indicates the curvature.

Visual surface analysis commands let you examine surfaces to determine smoothness as determined by its curvature, tangency, or other surface properties. These commands use NURBS surface evaluation and rendering techniques to help you visually analyze surface smoothness with false color or reflection maps so you can see the curvature and breaks in the surface.

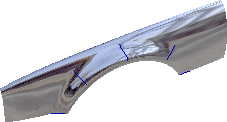

The EMap command displays a bitmap on the object so it looks like a scene is being reflected by a highly polished metal. This tool helps you find surface defects and validate your design intent.

The fluorescent tube environment map simulates tube lights shining on a reflective metal surface.

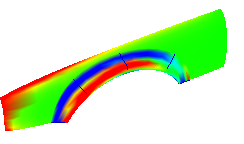

The CurvatureAnalysis command analyzes surface curvature using false-color mapping. It analyzes Gaussian curvature, mean curvature, minimum radius of curvature, and maximum radius of curvature.

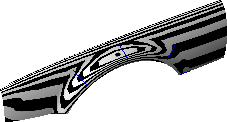

![]() The Zebra command displays surfaces with reflected stripes. This is a way to visually check for surface defects and for tangency and curvature continuity conditions between surfaces.

The Zebra command displays surfaces with reflected stripes. This is a way to visually check for surface defects and for tangency and curvature continuity conditions between surfaces.

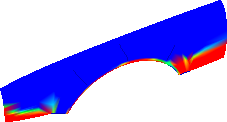

The DraftAngleAnalysis command displays by false-color mapping the draft angle relative to the construction plane that is active when you start the command.

The pull direction for the DraftAngleAnalysis command is the z-axis of the construction plane.

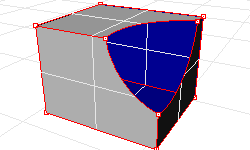

Geometry problems such as Boolean or join failures can be caused by edges on surfaces that have become broken or edges between surfaces that have been moved through point editing so they create holes. An edge is a separate object that is part of the surface’s boundary representation.

The ShowEdges command highlights all the edges of the surface.

A polysurface may look closed, but the Properties command may tell you that it is open. Some operations and export features require closed polysurfaces, and a model using closed polysurfaces is generally higher quality than one with small cracks and slivers.

Rhino provides a tool for finding the unjoined or “naked” edges. When a surface is not joined to another surface, it has naked edges. Use Properties command to examine the object details. A polysurface that has naked edges lists as an open polysurface. Use the ShowEdges command to display the unjoined edges.

Other edge tools let you split an edge, merge edges that meet end-to-end, or force surfaces with naked edges to join. You can rebuild edges based on internal tolerances. Other edge tools include:

| ● | SplitEdge splits an edge at a point. |

| ● | MergeEdge merges edges that meet end to end. |

| ● | JoinEdge forces unjoined (naked) edges to join nearby surfaces. |

| ● | RebuildEdges redistributes edge control points based on internal tolerances. |

Diagnostic tools report on an object’s internal data structure and select objects that may need repair. The output from the List, Check, SelBadObjects, and Audit3dmFile commands is normally most useful to a Rhino programmer to diagnose problems with surfaces that are causing errors.